Your Roadmap to a Road-Ready and Reliable Travel Trailer

Owning a travel trailer unlocks incredible freedom, but that freedom is built on a foundation of consistent and thorough maintenance. Neglecting your rig can lead to costly repairs, ruined vacations, and serious safety hazards on the highway. A small problem, like a cracked sealant seam or an underinflated tire, can quickly escalate into a trip-ending catastrophe if ignored. Preventative care is not just about avoiding expenses; it's about ensuring every journey is safe and enjoyable.

This is not just another generic list. We've created an actionable, comprehensive travel trailer maintenance checklist designed for RVers who demand reliability from their home on wheels. We skip the fluff and get straight to the essential tasks that protect your investment and keep you on the road. Instead of vague advice, you will find specific, step-by-step instructions that are easy to follow.

We've broken down the most critical tasks by frequency (pre-trip, monthly, seasonal, annual) and by system, covering everything from the hitch to the taillights. Each checklist item details why it's important, how to perform the check, what tools you'll need, and the common failure signs to watch for. Following this guide will empower you to tackle maintenance with confidence, ensuring your travel trailer is ready for adventure whenever you are. This structured approach helps you build a solid maintenance routine, turning complex tasks into manageable habits. Your goal is a trouble-free RV experience, and this detailed checklist is your roadmap to achieving it.

1. Tire Inspection and Rotation

Your travel trailer’s tires are its only connection to the road, making their condition a non-negotiable safety priority. Unlike your tow vehicle, trailer tires endure unique stresses from side-loading during turns and long periods of static load while parked. Regular inspection and rotation prevent dangerous blowouts, correct uneven wear patterns, and maximize the lifespan of your investment, ensuring you arrive at your destination safely. This task is a cornerstone of any effective travel trailer maintenance checklist.

Why It’s Critical

A blowout on a travel trailer can cause catastrophic loss of control, leading to severe accidents and extensive damage to the trailer's siding, plumbing, and electrical systems. Consistent maintenance mitigates this risk. For example, a full-time RVer might integrate a tire check into their weekly routine, while a snowbird should perform a thorough inspection and rotation before their seasonal migration north or south.

How to Inspect and Rotate Your Tires

Follow this systematic approach for comprehensive tire care.

Monthly and Pre-Trip Inspection:

- Check Tire Pressure: Using a quality pressure gauge, check the PSI of each tire when cold (before driving). Inflate to the manufacturer’s recommendation, which is found on the trailer’s VIN sticker or tire sidewall, not the maximum pressure listed on the tire itself.

- Inspect Tread Depth: Use a tread depth gauge or the "penny test." If you can see all of Abraham Lincoln’s head when a penny is inserted into the tread, it’s time for a replacement (less than 2/32" of tread remains).

- Examine Sidewalls: Look for cracks, bulges, punctures, or scuffs. UV exposure is a major cause of sidewall cracking, even on tires with ample tread.

Annual or 6,000-8,000 Mile Rotation:

For tandem or triple-axle trailers, a proper rotation pattern is essential to even out wear. A common pattern is to move the front tires to the rear on the same side and cross the rear tires to the front on the opposite side (front-to-rear, rear-to-opposite-front). Document the date and mileage in your maintenance log.

Pro Tip: Invest in a high-quality portable air compressor and a tire pressure monitoring system (TPMS). A TPMS provides real-time data on tire pressure and temperature, alerting you to potential issues before they become emergencies on the highway.

2. Roof and Exterior Sealant Inspection

Your travel trailer's roof and exterior seals are the primary defense against water, the single most destructive element to an RV. Unlike a house, a trailer flexes and shifts during travel, placing constant stress on every seam, joint, and penetration point. A diligent inspection and maintenance routine for sealants prevents catastrophic water intrusion, which can lead to delamination, wood rot, mold, and thousands of dollars in structural repairs, making it an indispensable part of your travel trailer maintenance checklist.

Why It’s Critical

A small, unnoticed crack in the roof sealant around a vent can allow water to slowly seep into the ceiling and walls, causing hidden damage for months or even years. By the time a stain appears on the interior ceiling, the structural damage is often extensive and costly to fix. For example, a seasonal RVer who performs a thorough sealant check before winter storage can prevent melting snow from entering a compromised seal, while a full-time RVer traveling through diverse climates must inspect more frequently to address seal degradation from intense UV rays or temperature fluctuations.

How to Inspect and Maintain Your Sealants

A systematic, semi-annual inspection is the key to catching issues early.

Bi-Annual Inspection (Spring and Fall):

- Clean the Roof: Before inspecting, thoroughly clean the roof with an RV-safe cleaner and a soft-bristled brush to remove dirt and debris that can hide potential issues.

- Inspect All Seams: Carefully examine the self-leveling sealant around every vent, skylight, antenna, ladder mount, and along the front and rear cap seams. Look for any cracks, voids, peeling, or areas where the sealant is pulling away.

- Check Body Seams and Windows: Inspect the vertical and horizontal body seams, window frames, and access doors. Pay close attention to corners and any areas where trim pieces meet.

- Check Interior Ceilings: After a heavy rain, check the interior ceiling, especially inside cabinets and around vents, for any signs of water stains or discoloration.

As-Needed Maintenance:

If you find compromised sealant, clean the area with denatured alcohol, carefully remove any loose old sealant, and apply a new bead of the appropriate RV-specific sealant (e.g., Dicor self-leveling lap sealant for horizontal surfaces).

Pro Tip: Use a product like Eternabond tape for a long-lasting, semi-permanent repair over cracked but stable sealant. This provides an excellent waterproof barrier and is a great addition to your onboard repair kit for emergency fixes on the road.

3. Fresh Water System Sanitization

Your travel trailer’s fresh water system, including the tank, lines, and faucets, can be a breeding ground for bacteria, mold, and algae if left untreated. Sanitizing the system is a non-negotiable health and safety task, ensuring the water you use for drinking, cooking, and washing is clean and free of harmful contaminants. This process eliminates any lingering microorganisms from winterization or from questionable water sources, making it a critical part of any comprehensive travel trailer maintenance checklist.

Why It’s Critical

A contaminated water system can lead to serious gastrointestinal illnesses and ruin a camping trip. Stagnant water, especially in the warm, dark environment of an RV’s plumbing, accelerates bacterial growth. A seasonal traveler de-winterizing their rig for the spring must sanitize to remove any remnants of non-toxic antifreeze and kill any bacteria that grew during storage. Similarly, a full-time RVer should sanitize quarterly to maintain water quality, especially after filling up from a variety of sources.

How to Sanitize Your Fresh Water System

Follow these steps to ensure your water is safe and tastes fresh.

Seasonal or Quarterly Sanitization:

- Prepare the Solution: For every 15 gallons of tank capacity, mix ¼ cup of household bleach with one gallon of water. Never pour undiluted bleach directly into your fresh water tank.

- Add and Fill: Pour the bleach solution into the empty fresh water tank. Then, fill the tank completely with fresh water.

- Circulate the Water: Turn on the water pump and open every faucet (hot and cold), including the shower and toilet, one by one until you smell bleach. This confirms the solution has reached all parts of the system.

- Let It Sit: Allow the solution to sit in the tank and lines for at least 12 hours to effectively kill all contaminants.

- Drain and Flush: Drain the entire system completely. Refill the fresh water tank with clean water and flush the system again, running all faucets until the bleach smell is gone. You may need to flush two or three times.

Pro Tip: Before sanitizing, bypass your water heater to prevent the bleach solution from damaging its heating element and anode rod. Also, remove any inline water filters, as the chlorine will ruin them. Replace them with new filters after the system has been thoroughly flushed.

4. Brake System Inspection and Lubrication

Your travel trailer’s brake system is arguably the most important safety feature when towing. Unlike your vehicle's brakes, trailer brakes face the immense task of stopping thousands of pounds of rolling weight, often on demanding terrain. Regular inspection and lubrication of pads, drums, and mechanical components ensure you have reliable stopping power, preventing catastrophic brake failure and giving you full control in emergency situations. This crucial task is a non-negotiable part of any comprehensive travel trailer maintenance checklist.

Why It’s Critical

A malfunctioning brake system can lead to jackknifing, loss of control, and devastating accidents. Overheated or worn-out brakes simply won't perform when you need them most. For instance, a family descending a steep mountain pass relies entirely on their trailer's brakes to prevent dangerous momentum buildup. Neglecting this system is a risk that safety-conscious travelers should never take.

How to Inspect and Service Your Brakes

A systematic approach ensures all components of your trailer’s brake system are in safe, working order.

Pre-Trip and Quarterly Inspection:

- Test Brake Controller: In a safe, open area like an empty parking lot, drive slowly and manually activate the trailer brakes using your in-cab controller. You should feel a distinct and firm pull from the trailer as it brakes independently.

- Check Breakaway Switch: Pull the pin on your trailer's breakaway switch. The trailer brakes should lock up immediately. Reinsert the pin fully to release them. This confirms your emergency system is functional.

- Inspect Wiring: Visually check all brake wiring from the 7-pin connector back to the axles. Look for any frayed, cracked, or loose connections that could interrupt the signal to your brakes.

Annual or 12,000-Mile Service:

This deeper inspection often requires jacking up the trailer and removing the wheels and hubs. If you are not comfortable with this, hire a certified RV technician.

- Inspect Brake Shoes/Pads and Magnets: Examine the brake shoes for wear. Most have a minimum thickness specification (typically around 1/16"). Check the electromagnets for uneven wear or signs of shorting.

- Clean and Lubricate: Clean all dust and debris from the brake assembly using brake cleaner. Lubricate the brake backing plate contact points, actuator arm, and other moving parts with high-temperature brake grease.

- Adjust Brakes: Use a brake adjustment tool (spoon) to tighten the star adjuster until there is a slight drag when you spin the wheel, then back it off until the wheel spins freely (usually 1-2 clicks).

Pro Tip: When driving, pay attention to how your trailer feels. If you notice any unusual pulling, squealing, or grinding sounds during braking, pull over immediately to inspect the system. Consider upgrading to a modern electric brake controller that offers proportional braking for smoother, more responsive stopping power.

5. Propane System Safety Check

Your travel trailer’s propane (LP) system is the lifeblood for heating, cooking, and refrigeration, but it demands uncompromising respect and regular attention. Propane is a volatile fuel, and a leak can lead to fire, explosion, or carbon monoxide poisoning. A diligent safety check ensures all components, from the tanks to the appliances, are functioning correctly and free from dangerous leaks. This routine is a non-negotiable part of any comprehensive travel trailer maintenance checklist, safeguarding your property and your life.

Why It’s Critical

A compromised propane system is one of the most immediate dangers an RVer can face. For example, a winter camper relying on their furnace could face a life-threatening situation if a leak develops overnight. Similarly, a full-time RVer who frequently swaps tanks must be vigilant about checking connections each time to prevent slow, odorless leaks from regulator failure. Early detection of a cracked hose or loose fitting can prevent a catastrophic event.

How to Perform a Propane Safety Check

Follow this procedure to ensure your LP gas system is secure and operating safely.

Pre-Trip and Monthly Inspection:

- Visual Inspection: Examine propane tanks for rust or damage. Check hoses and pigtails for cracks, abrasions, or brittleness. Ensure regulators are covered and free of debris.

- Leak Test with Soapy Water: With the tank valve open, spray or brush a 50/50 solution of dish soap and water on all connections, including the tank valve, pigtails, regulator fittings, and main line connections. If you see bubbles forming, you have a leak. Immediately close the tank valve and tighten or replace the faulty component.

- Appliance Function Test: One by one, light each propane appliance (furnace, water heater, stovetop, refrigerator) to ensure they ignite properly and maintain a steady, blue flame. A yellow, sputtering flame can indicate a problem with the regulator or the appliance itself.

- Detector Check: Test your propane and carbon monoxide detectors by pressing the "test" button. Ensure the batteries are fresh, replacing them every six months.

Pro Tip: If you ever smell the distinct "rotten egg" odor of propane, do not operate any electrical switches or create a spark. Immediately evacuate the RV, shut off the gas at the tank, and allow the area to ventilate before investigating the source.

6. Battery Maintenance and Testing

Your travel trailer’s deep-cycle house batteries are the heart of its off-grid capabilities, powering everything from lights and water pumps to furnaces and slide-outs. Unlike your tow vehicle's starter battery, these are designed for sustained power delivery and deep discharging. Diligent maintenance prevents unexpected power failures, extends battery life, and ensures all your 12-volt systems function reliably, making it an essential part of any travel trailer maintenance checklist.

Why It’s Critical

A dead battery bank can abruptly end a boondocking trip, leaving you without lights, heat, or running water. For RVers relying on solar power, healthy batteries are crucial for storing energy to use overnight or on cloudy days. Proper care prevents premature failure, which can be a costly replacement, and ensures your critical systems like the refrigerator control board or CO detector remain operational.

How to Maintain and Test Your Batteries

Follow this routine to keep your 12-volt system in peak condition.

Monthly Inspection and Testing:

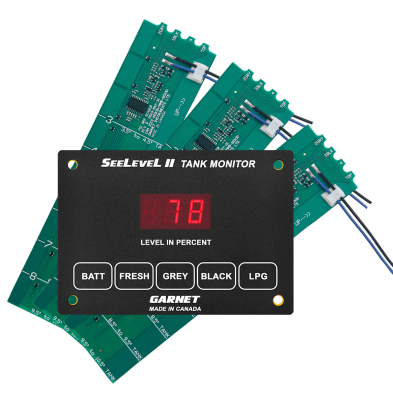

- Check Voltage: With the trailer unplugged and no major appliances running, use a multimeter to check the battery voltage. A fully charged 12-volt lead-acid battery should read around 12.6-12.8 volts. A reading below 12.2 volts indicates it's less than 50% charged and should be recharged immediately to prevent damage.

- Clean Terminals: Visually inspect terminals for fuzzy, white, or blue-green corrosion. Disconnect the batteries (negative cable first) and clean the posts and cable clamps with a wire brush and a paste of baking soda and water. Rinse with clean water, dry thoroughly, and reconnect (positive cable first).

- Inspect Water Levels (Flooded Lead-Acid Only): If you have serviceable batteries, wear safety glasses and gloves, then carefully pop the cell caps. The electrolyte fluid should cover the lead plates. If low, top off only with distilled water.

Seasonal and Annual Checks:

- Verify Charging System: While connected to shore power, use your multimeter to confirm the converter or charger is working. The voltage at the battery terminals should be between 13.6 and 14.8 volts.

- Load Test: To get a true sense of battery health, perform a load test annually. This simulates a heavy draw and measures the battery's ability to hold voltage. Many auto parts stores will perform this test for free.

Pro Tip: Upgrade to a smart battery monitor, like those from Victron. It provides a precise state-of-charge percentage, so you know exactly how much power you have left, rather than guessing based on voltage. This is the single best tool for preventing over-discharge and maximizing battery lifespan.

7. Plumbing System Inspection and Winterization

Your travel trailer’s plumbing system, encompassing fresh, grey, and black water tanks, is crucial for comfort and sanitation on the road. Unlike a residential system, RV plumbing is exposed to vibrations, extreme temperatures, and periods of disuse, making it vulnerable to leaks, clogs, and freeze damage. Proper inspection and seasonal winterization are essential to prevent catastrophic water damage, foul odors, and system failures, preserving the integrity and value of your rig. This step is a non-negotiable part of any comprehensive travel trailer maintenance checklist.

Why It’s Critical

A single forgotten water line that freezes and cracks can cause thousands of dollars in damage to your trailer's subfloor, cabinetry, and insulation. For RVers in northern climates, winterization is an absolute must before the first freeze. Even snowbirds storing their rig for a season must ensure the system is properly prepared to prevent stale water and bacterial growth. Consistent care ensures you have a reliable water supply when you need it and avoids costly, trip-ending emergencies.

How to Inspect and Winterize Your Plumbing

A systematic approach ensures no part of the plumbing system is overlooked.

Annual Inspection and Sanitization:

- Inspect All Connections: Visually check every water line, P-trap, and faucet connection for signs of leaks or drips. Pay close attention to the fittings at the water pump and water heater.

- Test Drains: Run water through every sink and the shower to ensure they drain quickly without gurgling, which can indicate a partial blockage.

- Sanitize the Fresh Water System: At the beginning of each camping season, sanitize your fresh water tank and lines using a solution of 1/4 cup of household bleach for every 15 gallons of water. Let it sit for several hours, then flush the entire system until the bleach smell is gone.

Seasonal Winterization:

Before temperatures drop below freezing, you must protect your system.

- Drain all water from the fresh, grey, and black tanks, as well as the water heater.

- Bypass the water heater to avoid filling it with antifreeze.

- Introduce non-toxic RV antifreeze into the system using the water pump.

- Open each faucet (hot and cold) one at a time until pink antifreeze flows out.

- Flush the toilet until antifreeze appears in the bowl.

- Pour a small amount of antifreeze into each sink drain and the shower P-trap.

Pro Tip: Create a laminated winterization checklist and keep it inside a plumbing access panel. This ensures you never miss a step, like the often-forgotten outdoor shower or low-point drains, which are common failure points if not properly addressed.

8. Slide-Out Mechanism Lubrication and Inspection

Your travel trailer’s slide-outs transform a compact space into a comfortable living area, but their complex mechanisms require regular attention. These systems, whether electric or manual, involve gears, tracks, and motors that operate under significant stress. Consistent lubrication and inspection prevent jerky movements, costly motor burnout, and gear failure, ensuring your extra living space deploys smoothly every time. This preventative step is a crucial part of any comprehensive travel trailer maintenance checklist.

Why It’s Critical

A stuck slide-out can ruin a trip, either trapping you inside or preventing you from packing up to leave. Debris in the tracks can cause gears to strip, while dry, unlubricated parts lead to excessive strain on the motor and can cause it to fail prematurely. For instance, a full-time RVer who frequently moves will want to perform this check monthly, whereas a seasonal camper should lubricate their slides before their first trip of the season and before winter storage.

How to Inspect and Lubricate Your Slide-Outs

Follow this procedure to keep your slide mechanisms in top working order.

Quarterly and Pre-Trip Inspection:

- Clean the Tracks and Gears: With the slide-out extended, use compressed air or a stiff brush to thoroughly clean all visible tracks, rails, and gear teeth. Remove any leaves, twigs, dirt, or road grime that has accumulated.

- Inspect for Damage: Carefully examine the mechanism for any bent tracks, broken gear teeth, or loose fasteners. Check electrical wiring for any signs of fraying or damage.

- Lubricate Moving Parts: Apply a dry, silicone-based lubricant specifically designed for RV slide-outs to the tracks and gears. Avoid using heavy, wet greases like lithium, as they attract and hold dirt, which can create a damaging abrasive paste.

- Condition the Seals: While the slide is extended, inspect the rubber seals around the entire perimeter. Clean them with soap and water, then treat them with a UV-protectant spray to prevent them from cracking and drying out, which can lead to water leaks.

Functional Test:

After cleaning and lubricating, operate the slide in and out two to three times to ensure the lubricant is evenly distributed and the mechanism moves smoothly without hesitation or unusual noises.

Pro Tip: Always check that the travel trailer is perfectly level before operating the slide-outs. Extending or retracting them on an unlevel surface puts the entire mechanism in a bind, which is a leading cause of motor and gear damage.

9. Exterior Paint and Body Caulk Maintenance

Your travel trailer’s exterior is its first line of defense against the elements, from harsh UV rays to driving rain and road debris. Proper maintenance of the paint, gel coat, and body caulk goes beyond aesthetics; it's a critical task that protects the underlying structure from water intrusion and costly delamination. Including this in your travel trailer maintenance checklist preserves your RV's resale value and prevents small, manageable issues from becoming major, trip-ending structural failures.

Why It’s Critical

The caulking and sealants around windows, doors, vents, and trim are designed to flex with the trailer's movement, but they degrade over time due to UV exposure and weather. A cracked or peeling sealant is a direct pathway for water, which can silently destroy the trailer's wooden frame, insulation, and interior walls. For example, a full-time RVer in the sunbelt should inspect their caulk quarterly, as intense sun can accelerate sealant failure, while a weekend camper should perform a thorough wash, wax, and inspection at the beginning and end of each camping season.

How to Maintain Your Exterior and Caulk

A proactive approach will keep your rig looking great and, more importantly, completely sealed.

Quarterly and Seasonal Inspection:

- Wash the Exterior: Use an RV-specific, pH-balanced soap that won’t strip existing wax. Work from top to bottom, rinsing thoroughly to avoid soap residue.

- Inspect All Seams: Carefully examine every sealed seam on the body. Look for any signs of cracking, peeling, or gaps in the caulk, paying close attention to corners, roof-mounted accessories, and window frames. Gently press on the siding near seams; a spongy or soft feeling can indicate underlying water damage.

- Check Paint and Decals: Look for paint chips, which can lead to rust on metal components, and peeling or faded decals.

Annual Maintenance:

- Apply Wax or Protectant: After a thorough wash, apply a quality RV wax or a modern ceramic coating. This creates a barrier against UV rays, oxidation, and road grime, making future cleanings much easier.

- Reseal as Needed: If you find failed caulk, carefully remove the old sealant with a plastic scraper to avoid damaging the finish. Clean the area with denatured alcohol and apply a new bead of high-quality, RV-specific sealant like Dicor Lap Sealant (for horizontal surfaces) or ProFlexRV (for vertical surfaces).

Pro Tip: Don't use silicone-based sealants from a home improvement store. They don't adhere well to RV materials and future sealants won't stick to the residue they leave behind. Always use products specifically formulated for RVs.

10. Coupling and Hitch System Inspection

Your hitch and coupling system is the critical link between your tow vehicle and your travel trailer. This connection manages immense forces, including tongue weight, braking stress, and turning torque. Regular inspection of the coupler, hitch ball, safety chains, and electrical connections is an essential part of any travel trailer maintenance checklist, directly preventing catastrophic failures like trailer detachment and ensuring your safety on the road.

Why It’s Critical

A failure in the hitch system can lead to a complete separation of the trailer from the tow vehicle, a terrifying and often tragic scenario. Even less dramatic issues, like a faulty electrical connection, can cause brake or light failures, leading to accidents. RV rental companies enforce strict hitch inspection protocols for this reason, and safety-conscious travelers make it a non-negotiable part of their pre-trip routine.

How to Inspect Your Hitch System

A thorough inspection before every trip is the best way to ensure a secure connection.

Pre-Trip Inspection:

- Check Coupler and Hitch Ball: Verify that the hitch ball size (e.g., 2" or 2 5/16") matches the coupler specification stamped on the trailer's tongue. Inspect the coupler latch for smooth operation and ensure it seats securely over the ball. Look for cracks, excessive wear, or deformation on both components.

- Inspect Safety Chains: Check chains and hooks for rust, cracks, or worn links. When connected, they should cross under the coupler and have just enough slack to allow for turns without dragging on the ground.

- Test Electrical Connections: Connect the 7-pin plug and have a partner check all lights: running lights, brake lights, and turn signals. Inspect the plug and vehicle-side socket for corrosion or bent pins. Apply dielectric grease periodically to prevent moisture damage.

- Verify Breakaway Cable: Ensure the breakaway cable is securely attached to the tow vehicle (not the hitch itself) and is in good condition, free of frays or damage.

Pro Tip: Use a tongue weight scale to measure your trailer's tongue weight and ensure it is between 10-15% of the total loaded trailer weight (GTW). Proper tongue weight is crucial for preventing dangerous trailer sway and maintaining control.

10-Point Travel Trailer Maintenance Comparison

| Item | Implementation Complexity 🔄 | Resources & Speed ⚡ | Expected Outcomes ⭐📊 | Ideal Use Cases 💡 | Key Advantages 📊 |

|---|---|---|---|---|---|

| Tire Inspection and Rotation | Medium 🔄 — monthly checks + periodic rotation | ⚡ Tools: pressure gauge, jack, TPMS; Time: short monthly / rotation every 6–8k mi; Cost: low–moderate | ⭐⭐⭐⭐⭐ — prevents blowouts; +20–30% tire life; better fuel efficiency 📊 | Regular travelers, fleet operators, seasonal migration | Prevents dangerous blowouts; improves towing stability; affordable prevention |

| Roof and Exterior Sealant Inspection | Medium–High 🔄 — working at heights, seam work | ⚡ Tools: ladder, caulking gun, roof coating; Time: annual inspection; Cost: low–moderate | ⭐⭐⭐⭐ — prevents water intrusion and expensive interior damage 📊 | Pre-storage, post-storm checks, seasonal maintenance | Stops leaks before major damage; extends structural life |

| Fresh Water System Sanitization | Low–Medium 🔄 — simple procedure but time-consuming | ⚡ Tools: food‑grade bleach, hoses, test kit; Time: 2–3 hours; Cost: low | ⭐⭐⭐⭐ — eliminates bacteria/musty odors; ensures potable water 📊 | Before first use, seasonal prep, full-time RVers | Ensures safe drinking water; inexpensive and DIY-friendly |

| Brake System Inspection and Lubrication | High 🔄 — technical inspection and fluid work | ⚡ Tools: brake tools, fluid, possible pro; Time: moderate; Cost: moderate–high | ⭐⭐⭐⭐⭐ — prevents brake failure; improves stopping performance 📊 | Pre-towing season, heavy towing, commercial use | Critical for towing safety; identifies problems early |

| Propane System Safety Check | Medium 🔄 — visual + simple tests; some certified work | ⚡ Tools: soapy water, detector, basic tools; Time: quick checks / annual pro; Cost: low–moderate | ⭐⭐⭐⭐⭐ — prevents leaks, explosions, CO risk 📊 | Anytime using propane; pre-winter heating season | High safety impact; quick detection of dangerous leaks |

| Battery Maintenance and Testing | Low–Medium 🔄 — routine testing; upgrades add complexity | ⚡ Tools: multimeter, load tester, monitor; Time: monthly checks; Cost: low–high (lithium) | ⭐⭐⭐⭐ — reliable off‑grid power; fewer unexpected failures 📊 | Boondocking, solar systems, full-time living | Ensures dependable power; extends battery life; enables off‑grid use |

| Plumbing Inspection & Winterization | Medium 🔄 — multi-step winterization and checks | ⚡ Tools: RV antifreeze, pump, hoses; Time: 2–4 hours; Cost: low–moderate | ⭐⭐⭐⭐ — prevents freeze damage; avoids costly repairs (>$5k) 📊 | Cold climates, storage prep, winter campers | Prevents burst pipes; preserves system integrity for winter use |

| Slide-Out Mechanism Lubrication & Inspection | Medium 🔄 — mechanical/electrical inspection | ⚡ Tools: silicone lubricant, brushes, basic tools; Time: periodic; Cost: low–moderate | ⭐⭐⭐⭐ — smooth operation; reduces risk of $2k–5k repairs 📊 | Frequent slide users, full-time RVers, seasonal checks | Prevents costly mechanical failure; maintains living-space usability |

| Exterior Paint & Body Caulk Maintenance | Low–Medium 🔄 — detail work and caulking | ⚡ Tools: soap, wax/coating, caulk; Time: monthly wash / annual polish; Cost: low–high (pro detailing) | ⭐⭐⭐⭐ — preserves appearance and resale value; prevents fiberglass damage 📊 | Sellers, sun-exposed climates, long-term owners | Protects against UV/weathering; preserves resale value |

| Coupling & Hitch System Inspection | Low–Medium 🔄 — visual + functional checks | ⚡ Tools: scale, test light, grease; Time: quick pre-trip; Cost: low | ⭐⭐⭐⭐⭐ — prevents detachment; ensures lights/brakes function 📊 | Every tow, heavy loads, rental fleets | Prevents accidents; ensures proper weight distribution and connections |

From Checklist to Confidence: Your Journey Starts Here

Navigating the world of RV ownership can feel overwhelming, but as we've detailed throughout this guide, a proactive approach to maintenance is the single most powerful tool you have. This comprehensive travel trailer maintenance checklist isn't just another list of chores to add to your to-do list; it's a strategic roadmap designed to transform you from a reactive owner into a confident, prepared traveler. By systematically addressing each checkpoint, from pre-trip inspections to annual deep dives, you are building a foundational understanding of your rig's intricate systems.

You've learned not just what to check, but why it matters. A simple tire pressure check isn't about air; it's about preventing a catastrophic blowout on a busy highway. Inspecting your roof sealants isn't just about looking for cracks; it's about stopping a silent, destructive water leak that can compromise your RV's entire structure. Every task, from sanitizing your fresh water system to lubricating your slide-out mechanisms, is a direct investment in the safety, reliability, and longevity of your mobile home.

The True Value of Proactive Maintenance

The real benefit of following this travel trailer maintenance checklist extends far beyond just preventing mechanical failures. It's about cultivating peace of mind. When you know the condition of your brakes, have confidence in your propane system, and trust that your roof is watertight, you can fully immerse yourself in the adventure. You're no longer haunted by the "what ifs" that can plague a journey.

Consider the difference:

- Reactive Maintenance: A trip is suddenly derailed by a seized brake caliper or a leaking water line, leading to expensive emergency repairs, lost vacation time, and immense stress. Your plans are dictated by the failure.

- Proactive Maintenance: You identify a worn brake pad or a brittle water hose during a routine monthly check. You replace the part at your convenience, on your terms, and for a fraction of the cost of an emergency roadside service call. Your plans remain your own.

This shift in mindset is the core takeaway. Your travel trailer is a complex machine, but it is not a mystery. By engaging with it regularly, you demystify its operations and empower yourself to handle issues before they become crises.

Making the Checklist Your Own

This guide provides the framework, but the ultimate goal is to make it your own. We encourage you to take the next crucial step: create a personalized maintenance log. Use a simple notebook, a spreadsheet, or a dedicated app to track your progress.

Your log should include:

- Task: The specific maintenance item (e.g., "Inspected and re-sealed front cap seams").

- Date Completed: When the task was performed.

- Notes: Any observations, such as "sealant showed minor cracking," or "used two tubes of Dicor self-leveling lap sealant."

- Parts/Products Used: Record specific brands and part numbers for easy reordering.

- Next Due Date: Set a reminder for the next inspection or service.

This log becomes an invaluable historical record of your RV. It helps you anticipate future needs, simplifies troubleshooting, and significantly increases your rig's resale value by demonstrating a consistent history of meticulous care. Following a detailed travel trailer maintenance checklist and documenting your work is the hallmark of a responsible and savvy RV owner. Your journey to mastery begins not on the road, but in your driveway with a caulk gun, a wrench, and the determination to be prepared.

Ready to tackle your checklist? Don't let a missing part or the wrong sealant slow you down. For every item on this list, from specialized lubricants and roof sealants to replacement water filters and brake components, RVupgrades.com has the high-quality parts you need from the industry's most trusted brands. Visit RVupgrades.com today and stock your maintenance toolkit with everything required to keep your travel trailer safe, reliable, and ready for adventure.