When your RV slide out decides to stay put, it's almost always an issue with power or a simple safety lock. Before you start thinking the worst, run through the basics: make sure your RV is level, the parking brake is on, and your house batteries are showing a healthy charge (that's 12.6 volts or more). If that doesn't do the trick, the next stop is the fuse panel.

Your First Response Checklist for a Stuck RV Slide Out

There's a unique kind of dread that hits when you press the slide out switch and are met with… silence. It's a feeling I know well, and it's a common headache for RVers. But before your mind spirals to blown motors or tangled wiring, take a breath. Most of the time, the fix is something simple you might have overlooked in the rush to get camp set up.

Picture this: you've just pulled into the perfect spot, ready to kick back, but your living room is stuck at half-size. You're not alone. Slide-out failures are one of the most frequent complaints I hear from fellow owners. The electric systems, in particular, can be finicky. They rely on powerful 12-volt DC motors that need a lot of juice to get moving, and they'll happily trip a breaker or blow a fuse at the first sign of trouble. You can get more details on how these systems work from RV service experts.

Confirming the Non-Negotiable Basics

RV slide outs are incredibly powerful and can do some serious damage if they're operated the wrong way. That's why manufacturers build in a handful of safety interlocks. If these conditions aren't met, the slide simply won't get any power.

Think of it as a pre-flight checklist before you expand your living space:

- Is the RV Level and Stable? Trying to run a slide out on uneven ground is a recipe for disaster. It can twist the frame and cause the whole mechanism to bind up. Always level your rig and drop your stabilizers before you even think about hitting that button.

- Is the Parking Brake Engaged? On most motorhomes, this is a non-negotiable. The slide out is wired right into the parking brake sensor as a safety measure. Make sure it's set, and set firmly.

- Is the Ignition Off? Just like the parking brake, many systems won't operate if the key is in the ignition, especially if it's turned to the "on" position.

Getting these steps right is foundational. I've seen more "broken" slide outs fixed by simply setting the parking brake than I can count.

Pro Tip: I always do a quick walk-around before touching the slide controls. It’s amazing what you’ll find. I’m looking for low-hanging branches, the campground power pedestal, or even a picnic table I might have set down too close. A two-minute walk can save you a thousand-dollar repair.

Before diving deeper into fuses and motors, a quick once-over on these common culprits can save you a world of frustration. I've put together a simple table to guide you through these initial diagnostics.

Initial Diagnostic Checklist

| Check | What to Look For | Actionable Fix |

|---|---|---|

| Safety Interlocks | Parking brake status, ignition key position, and leveling jack deployment. | Engage the parking brake firmly. Remove the key from the ignition. Ensure the RV is level before operating. |

| Power Source | Battery voltage reading on your monitor (should be 12.6V+), shore power connection, battery disconnect switch. | Charge batteries if low. Confirm shore power is active. Turn the battery disconnect switch to "ON." |

| Obstructions | Anything outside (trees, posts) or inside (furniture, rugs) that could block the slide's path. | Perform a full walk-around and clear any physical blockages before attempting to operate the slide again. |

| Fuses/Breakers | Blown fuses in the main 12V panel or tripped resettable breakers, often located near the batteries. | Inspect the slide-out fuse; replace with the exact same amperage if blown. Press the small reset button on any circuit breakers. |

Running through this checklist handles about 80% of slide-out issues. If you've gone through these steps and are still stuck, it's time to look a little closer at the electrical system itself.

Checking Your Power Supply

Nine times out of ten, a stubborn slide out is just plain hungry for power. Those motors are power hogs, and any weakness in your 12-volt system will stop them in their tracks.

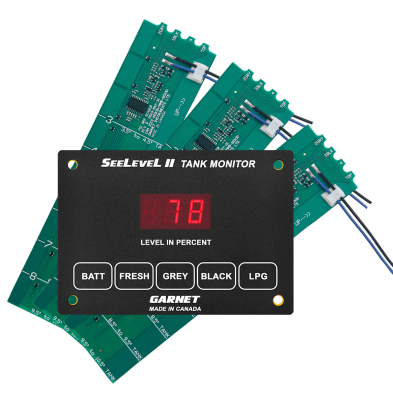

Start with your house battery. A slide out motor trying to move a few thousand pounds can easily draw 15-20 amps or more. A weak or dying battery just can't deliver that kind of punch. Your battery monitor needs to show at least 12.6 volts for a full charge. If you’re plugged into shore power, your converter should be handling the load, but a dead battery or a faulty converter can still be the problem. And don't forget the battery disconnect switch (sometimes called a "salesman switch")—make sure it's ON.

If the batteries look good, it's time to check the circuit protection. Find your main 12V fuse panel. The diagram on the panel door should point you to the slide out's fuse. Pull it out and hold it up to a light. If that little metal strip inside is broken, the fuse is blown. Replace it, but only with a fuse of the exact same amperage. Using a higher-rated fuse is asking for a fire.

Some RVs, especially ones with hydraulic slides, use resettable circuit breakers instead. These usually look like small black boxes with a tiny reset button on the side and are often found in a compartment near your batteries. If you find one, give that little button a firm press. You might just hear a click and find your problem is solved.

Diagnosing Common Electric Slide Out Problems

If the basic safety and power checks didn't get your slide-out moving, it's time to follow the electrical trail. This is where a bit of patience and a multimeter become your new best friends. Most modern RVs use electric systems from big names like Lippert or Schwintek, and while they might look intimidating, their electrical guts are actually pretty logical.

Your diagnostic journey starts right where you give the command: the slide-out switch. It’s a common point of failure simply due to how much it gets used. With a multimeter, you can quickly find out if power is flowing through it correctly. If you've got 12V power going in but nothing coming out when you press it, you’ve found your culprit.

From the switch, power makes its way to the slide-out control module. This little electronic brain is often the key to figuring out why your slide-out is on strike. Many controllers, especially on Lippert and Schwintek systems, have a slick built-in diagnostic feature that uses blinking LED lights.

Decoding the Control Module Fault Codes

Don't just glance past those little blinking lights on the controller; they're trying to tell you something. Manufacturers put these codes in to save you hours of guesswork. You'll need to check your specific system's manual, but the patterns often point directly at the problem.

- A certain number of green flashes could mean low voltage, a very common issue if your house batteries are running low.

- Red flashes usually signal something more serious, like a short circuit in a motor or its wiring.

For instance, on a lot of Lippert controllers, eight red flashes means a short in the wires for motor one, while nine flashes points the finger at motor two. This kind of intel is gold, narrowing your search from the whole system down to one component and its wiring.

A dead slide-out can feel like a massive mechanical failure, but I’ve found that more than half the time, it's a simple electrical issue. Before you assume the worst, always trace the power from the switch to the motor. The problem is usually hiding in plain sight as a loose wire or a faulty controller.

This decision tree gives you a simple visual path to follow, helping you systematically check the most common culprits when your slide-out is stuck.

Following this flow makes sure you don't skip a critical first step, like checking battery power or leveling, before you dive into the deeper diagnostics.

Inspecting Wires and Connections

Once you've checked the controller, your next move is to get your eyes on the wiring harness. This is where all the vibrations from the road can create real headaches. Look for any areas where wires might be rubbing up against the frame.

Keep a close eye on these potential failure points:

- Chafing: Search for spots where the wire's outer sheath is worn through, exposing the copper strands inside. This is a short circuit waiting to happen.

- Corrosion: Check every connector, especially those underneath the RV that are exposed to the elements. That green or white crusty stuff is a dead giveaway for corrosion that can kill the power flow.

- Loose Connections: Gently tug on the wires at every connection point—the switch, the controller, and the motor. A spade connector or screw terminal that has worked itself loose is a surprisingly common and easy fix.

When you're trying to figure out complex mechanical failures, it sometimes helps to think about the bigger picture. For example, understanding equipment breakdown in a general sense can provide some useful perspective on what might cause your slide-out issues, even if the context is totally different.

Testing the Slide Out Motor Directly

If the switch, controller, and wiring all seem fine, the last stop on the line is the motor itself. The most definitive test is to bypass the entire control system and give the motor power directly. This will tell you, once and for all, whether the motor is dead or if the problem is somewhere else.

Safety First: Before you do anything, disconnect the motor leads from the control module. This is absolutely critical. You don't want to accidentally send power back into the controller and fry it.

Using a set of jumper wires from a good 12V battery, briefly touch the wires to the motor leads. If you swap the positive and negative wires, the motor should run in the opposite direction. If it spins smoothly both ways, your motor is healthy. If it does nothing, just hums, or sparks, the motor has given up the ghost.

If you confirm a bad motor, we've got a ton of great info and replacement options in our RV slide out motor replacement guide.

Troubleshooting Tough Hydraulic Slide Out Systems

Hydraulic slide outs are the heavy lifters of the RV world, moving massive rooms with incredible force. But when they decide not to work, the problems look a lot different than their electric cousins. If you hit that switch and all you get is a high-pitched whine from the pump motor but no slide movement, your first stop should be the heart of the system: the hydraulic fluid reservoir.

Now, this isn't as simple as checking the oil in your car. The correct fluid level in a hydraulic system depends entirely on whether your slides are in or out. The golden rule—and you should always double-check your owner's manual—is to check the fluid with all your slides pulled fully in. If you top it off with the slides extended, you're asking for trouble. When you retract them, all that extra fluid has nowhere to go, and you’ll likely blow out your seals and create a giant, oily mess.

That strained whining sound you hear? That's the pump's cry for help. It’s trying to build thousands of pounds of pressure with air instead of fluid, and it’s the number one symptom of low fluid.

Checking and Topping Off Hydraulic Fluid

First things first, you've got to find the reservoir. It's usually a translucent tank bolted to the hydraulic pump, often tucked away in a front storage bay.

With your slides retracted, take a look at the fluid level. It should be sitting comfortably between the "Full" and "Add" lines. If it's low, you'll need to add some. Most RV hydraulic systems run on a specific type of Automatic Transmission Fluid (ATF). Again, check your manual, but common fluids are Dexron III or Mercon V. Whatever you do, never mix different types of fluid.

Crucial Tip: Hydraulic fluid doesn't just evaporate. If your level is low, it’s almost a guarantee you have a leak somewhere. Topping it off is just a temporary fix; your real job is to put on your detective hat and hunt down that leak before it turns into a major failure.

Listening for the Solenoid Click

Once you've confirmed the fluid is good to go, the next step is to use your ears. Find the pump assembly and you'll see one or more solenoids attached to it. These are basically small electromagnetic gates that direct the hydraulic fluid to the right hoses to either push the slide out or pull it in.

Grab a helper and have them press the slide out switch while you're standing near the pump. The instant they hit that switch, you should hear a sharp, distinct 'click', immediately followed by the hum of the pump motor. That click is the sound of a happy solenoid doing its job.

- You hear a click, the pump runs, but nothing moves: This circles back to a fluid or pressure problem. It could be an internal leak in a valve or a significant leak somewhere in the lines.

- The pump runs, but you hear no click: This is a classic sign the solenoid isn't opening. The solenoid itself could be bad, it might have a loose wire, or the control board isn't sending the signal.

- You hear absolutely nothing—no click, no pump: Time to look upstream. This points to an electrical issue like a blown fuse, tripped breaker, or a faulty switch, which you've hopefully already checked.

Hunting for Hydraulic Leaks

A tiny hydraulic fluid leak can quickly become a catastrophic failure, leaving a trail of red ATF all over your campsite and RV underbelly. Catching these leaks early is everything.

Start your inspection right at the pump, checking every fitting and hose connection for any sign of weeping. From there, slowly trace the hydraulic lines as they snake along the RV's frame toward the big hydraulic rams that move the slide room. You're looking for the tell-tale signs: an oily film, dirt and road grime clinging to a wet spot on a hose, or an obvious drip.

Pay extra close attention to the crimped metal fittings on the ends of the hoses—these are notorious failure points. Even a small drip from one of these fittings is a ticking time bomb. It's a clear warning that the hose needs to be replaced before it bursts under the system's immense operating pressure.

How To Manually Override Your Slide Out

When all your troubleshooting hits a brick wall and you're stuck at a campsite with a slide that refuses to budge, the manual override is your get-out-of-jail-free card. Think of it as your last resort to get the room pulled in so you can safely get back on the road.

Every single RVer should know this process for their specific rig. I can tell you from experience, the worst time to learn is under pressure, in the dark, with a storm rolling in. Do yourself a favor and practice this in your driveway on a calm afternoon so you know exactly what to do when it counts.

Manually Retracting Electric Slide Outs

Electric systems can vary a bit, but the override process usually comes down to one of two things: disengaging the motors or using a manual crank. The absolute key here is to grab your owner's manual—it will pinpoint your exact system and where the override access point is hiding.

For the incredibly popular Schwintek in-wall systems, the process is a bit more hands-on. You'll need to find the slide out controller and unplug the motors. On a lot of models, you can then spot a small retention screw on the exterior of the slide, near the top of the track on each side. Removing that screw lets the motors lift up, disengaging them from the gear tracks. At that point, it becomes a team effort—you'll need a few friends to help physically and evenly push the room back into the RV.

Other electric systems, like many from Lippert, make it a little easier by providing a dedicated spot for a manual crank.

- Look for a small access hole or a hex nut on the end of the motor shaft. This is often on the opposite side of the RV from the slide itself.

- You'll need a socket wrench with an extension or a specific crank tool that came with your RV.

- Turn the crank or nut clockwise to bring the slide in. It’s going to be slow work and take some muscle, but it absolutely gets the job done.

Overriding a Hydraulic Slide Out System

Hydraulic systems use a totally different method that usually involves the pump and a good cordless drill. The whole process relies on a manual override valve located right on the pump assembly.

First thing's first: find your hydraulic pump. You'll see a small valve or hex screw on the pump motor. Using an Allen key or wrench, you'll open this valve—it usually only takes a quarter or half turn. This is what releases the hydraulic pressure that's holding the slide out.

Next, you'll spot a fitting on the end of the pump motor that a hex bit for your cordless drill will fit perfectly. Pop the bit in and run the drill in reverse (counter-clockwise) to manually pump the fluid back and retract the slide. Once the room is all the way in, don't forget the most important step: close the override valve to lock it in place for travel.

Mechanical failures in RV slide-outs can pop up without warning. It's often the result of the brutal cycle of extension and retraction, combined with all the vibrations from the highway. Whether you have a rack-and-pinion, cable, hydraulic, or electric system, all types eventually see wear on their gears, motors, and rams. Learning how to perform an emergency override with a manual crank or drill is a crucial skill. You can learn more about the different types of slide out systems and their common issues.

Knowing how to manually operate your slide turns a potential trip-ending disaster into a manageable inconvenience. It's the skill that ensures you can always get your RV back into a road-safe condition, no matter what.

Preventive Maintenance To Keep Your Slide Out Working

Let's be honest, the best way to deal with a broken slide out is to make sure it never breaks in the first place. I've learned the hard way that proactive maintenance is a whole lot less stressful than wrestling with a stuck room at a campsite. A simple, consistent care routine can prevent the vast majority of issues that leave RVers stranded.

Think of your slide out mechanism like any other complex system on your rig—it needs regular attention. Over a camping season, it's exposed to road grime, rain, and extreme temperatures, all while moving thousands of pounds. A little care really does go a long way.

Cleaning and Lubricating Mechanical Parts

If you take away one thing from this section, let it be this: always start with a clean surface. Just spraying new lube over old, gritty grease creates a grinding paste that will absolutely chew up your gears. I’ve seen it happen.

First, extend the slide out completely so you can see all the moving parts. Grab a soft brush and some degreaser (or just mild soap and water) and give the rack-and-pinion gears, slide arms, and rollers a good cleaning. You want to get all the old gunk, road dust, and any stray debris out of there. Once it's spotless and dry, you’re ready to lubricate.

The type of lubricant you use is critical. Whatever you do, avoid those heavy, greasy sprays. They might seem tough, but they're basically dirt magnets, attracting sand and grime that will gum up the mechanism and cause more harm than good.

Always opt for a high-quality dry lubricant with PTFE. This stuff sprays on wet, so it can penetrate all the nooks and crannies, but the carrier agent evaporates. It leaves behind a dry, slick film that won't attract dirt—perfect for the exposed gears on an RV slide out.

Apply the lubricant sparingly to all the gears, rollers, and slide tubes. You just need a light, even coat. Afterwards, run the slide in and out a couple of times to work the lubricant into all the moving surfaces.

Inspecting and Conditioning Rubber Seals

Your slide out seals do more than just keep rain out; they're actually a key part of smooth operation. Over time, these rubber seals get dry, cracked, and sticky. When they get sticky, they can practically glue themselves to the side of the RV. This forces the motor to work way harder to break the room free, which can lead to blown fuses, tripped breakers, or a burned-out motor.

At least twice a year, give every inch of your seals a good look. Check for tears, cracking, or spots where the seal is pulling away from the RV wall. Clean them with a mild soap and water solution, then treat them with a dedicated rubber seal conditioner. This keeps the rubber pliable and stops it from sticking. A happy seal not only prevents water damage but also takes a huge load off your entire slide out system. If you find your seals are too far gone, you can learn more about how to replace RV slide out seals.

Synchronizing Dual Motor Systems

If you've got a big slide out, you probably have a dual-motor system, like the popular Schwintek. These have two electric motors—one at the front and one at the back—that have to work in perfect harmony. If they fall out of sync, one side of the room moves faster than the other. This causes the slide to get crooked, bind up in the opening, and eventually grind to a halt.

Luckily, getting them back in sync is usually pretty easy.

- First, fully extend the slide out. Keep holding the "out" button for an extra 3-5 seconds after the room is fully extended and has stopped moving. You might hear the motors whine a bit; that’s normal.

- Then, fully retract the slide out. Bring the room all the way back in, and again, keep holding the "in" button for another 3-5 seconds after it’s fully retracted and stopped.

This simple procedure lets the electronic controller find the full-stop positions for both motors and resets their timing. I make it a habit to do this every few trips, or anytime the slide seems a little jerky. It's a crucial step to prevent a crooked and very stuck slide.

To help you stay on track, I've put together a simple checklist for seasonal maintenance.

Seasonal Slide Out Maintenance Schedule

Following a regular schedule is the easiest way to prevent major headaches. Here’s a simple checklist to help you stay on top of the essential tasks throughout the year.

| Maintenance Task | Frequency | Recommended Products |

|---|---|---|

| Clean & Lubricate Gears/Tracks | Every 3-4 months (or as needed) | Degreaser or mild soap, Dry lubricant with PTFE |

| Inspect & Condition Rubber Seals | 2-3 times per year (Spring & Fall) | Mild soap, Rubber seal conditioner spray or wipe |

| Synchronize Dual Motors | Every 2-3 months (or if operation is jerky) | N/A |

| Check for Debris on Slide Topper | Before every retraction | Broom or leaf blower |

| Inspect Wires & Connections | Twice per year | Visual inspection |

Sticking to a schedule like this turns a potentially trip-ruining problem into a quick and easy routine. A little bit of prevention is worth a pound of cure, especially when you're miles from home.

Common RV Slide Out Questions Answered

After you've run through the basic diagnostics, some slide out behaviors can still leave you scratching your head. I've been there. Over the years, I've seen a few common scenarios pop up time and time again. Understanding what's likely causing these specific issues can help you zero in on the right fix without chasing your tail on the wrong problem.

Here are some of the most frequent questions we hear from fellow RVers.

My RV Slide Out Goes Out A Little Then Stops

This classic stutter-and-stop issue is incredibly common, and from my experience, it almost always points to one of three culprits. The first and most likely suspect is low battery voltage. Slide motors are absolute power hogs, and a weak battery just can't deliver the high amperage they need to keep moving. Before you do anything else, check that your house batteries are fully charged and reading above 12.6V.

If your batteries are good, it could be a simple physical obstruction. Something could be binding up the system. I've seen it all—a bunched-up rug inside, a stray branch outside, or just gunk in the tracks. Take a minute to carefully inspect the interior and exterior paths.

Lastly, if you have a dual-motor system like a Schwintek, this behavior is a tell-tale sign the motors are out of sync. The fix is often as simple as resynchronizing them. Just fully retract the slide, then fully extend it, making sure to hold the button for a few extra seconds at the end of each cycle.

One Side Of My Slide Out Moves Faster Than The Other

The moment you see your slide out moving crooked, stop. Immediately. This is a clear warning of a serious issue that can quickly twist the slide box frame and lead to some major, expensive damage. For electric systems with two motors, this is the textbook symptom of the motors being out of sync.

The resynchronization procedure I mentioned above is your first line of defense here. If that doesn't straighten things out, the problem is likely more serious. You could be looking at a failing motor on the slow side, a loose wire starving that motor of power, or a mechanical issue in the track that’s creating drag. On hydraulic systems, a crooked slide often points to a problem with one of the hydraulic rams or a valve not opening correctly.

A crooked slide is never something to ignore. If a simple resync doesn't fix it, you need to investigate the cause thoroughly before operating it again. Continuing to force it can turn a manageable repair into a complete system rebuild.

What Does It Mean When I Hear A Clicking Or Grinding Noise

Unusual noises are your slide out’s way of screaming for help. Pay close attention, because the specific sound it makes is a valuable clue to what's gone wrong.

- Rapid Clicking: In an electric system, a fast clicking sound often means stripped gears inside the motor's gearbox or a sheared pin. This usually happens when the motor is under extreme stress, either from a jam or a badly misaligned track.

- Loud Grinding: A harsh, grating, grinding noise usually means something is physically interfering with the mechanism. This could be as simple as debris caught in the gear track or, more seriously, damaged gears that are no longer meshing properly.

In either case, stop operating the slide right away. Forcing it will only make things worse. You'll need to do a thorough visual inspection of all the mechanical parts to pinpoint where that noise is coming from before you try to move it again. Wondering what these fixes might run you? Our guide on RV slide out repair costs can give you a better idea of what to expect.

At RVupgrades.com, we stock all the parts you need to keep your slide out operating smoothly, from motors and controllers to seals and lubricants. Shop our extensive selection and get back to enjoying your extra space. https://www.rvupgradestore.com