Wiring your RV batteries in parallel is the secret to unlocking more off-grid power without overhauling your entire electrical system. It’s a straightforward project: you connect positive terminals to other positive terminals and negative to negative. The result? One big 12-volt battery bank that keeps your lights on and appliances humming for much, much longer. It's the go-to upgrade for anyone serious about extending their boondocking adventures.

Why Parallel Wiring Is Your Ticket to Longer Trips

Before you even think about touching a wire, let’s talk about why this is such a game-changer for RVers. Think of your battery’s capacity, measured in amp-hours (Ah), like its electrical fuel tank. A single 100Ah battery might get you through a chilly night with the furnace running, but you'll be watching your monitor like a hawk.

Wiring up a second identical battery in parallel instantly doubles your reserve to 200Ah.

This simple upgrade means you can run your heater, lights, and water pump, and even charge your phone all weekend without that nagging power anxiety. It’s the difference between rationing every watt and actually kicking back and relaxing.

Parallel vs. Series: The Critical Difference

It's really easy to mix up parallel and series wiring, but getting it wrong can cause major headaches for your RV. The distinction is simple but absolutely crucial.

- Parallel Wiring (More Runtime): You connect positive-to-positive and negative-to-negative. The voltage stays the same (12V), but the amp-hour capacity of each battery adds together. This is exactly what you want for your RV's house battery bank.

- Series Wiring (More Voltage): You connect positive-to-negative. The amp-hour capacity stays the same, but the voltage doubles (turning two 12V batteries into a 24V system). This is common in things like golf carts, but it’s the wrong setup for a standard 12V RV.

The whole point of a parallel connection is to build a bigger energy reserve. You’re simply combining the fuel tanks of multiple batteries into one larger, longer-lasting power source, all while keeping the system perfectly compatible with your RV's 12-volt electronics.

The Proven Standard for RV Power

This isn't some clever hack; it's the established best practice for RV electrical systems. In fact, parallel wiring is the industry standard, and most RVs on the road today use this exact configuration for their house batteries.

When you wire two 12-volt, 100-amp-hour batteries in parallel, you create a 12-volt, 200-amp-hour system. You've doubled your runtime without any complex changes. For a deeper dive into this concept, you can learn more about how battery connections work on vatrerpower.com. It's a reliable, straightforward way to build a robust power supply that’s ready for the freedom of the open road.

Gathering the Right Tools and Materials for a Safe Install

A reliable parallel battery bank is built with precision and the right components, not just wishful thinking. Think of this stage as your pre-flight checklist. Skipping a step here can lead to poor performance or even serious safety hazards down the road.

Getting this project right starts long before you ever touch a single terminal. It begins with the batteries themselves.

For a parallel bank to function as a single, healthy unit, the batteries must be identical twins. This is non-negotiable. They absolutely have to share the same:

- Battery Chemistry: Never, ever mix AGM with Lithium or flooded lead-acid. Each type has its own unique charging profile and internal resistance that makes them incompatible.

- Capacity (Ah): All batteries need to have the same amp-hour rating, like three 100Ah batteries.

- Age and Usage History: Pairing a brand-new battery with a seasoned veteran is a recipe for disaster. The old battery will drag the new one down, dramatically shortening the lifespan of your entire investment.

- Manufacturer and Model: Even batteries with similar specs from different brands can have tiny variations that will eventually cause imbalances in the bank.

An imbalanced bank is an inefficient and short-lived one. The stronger batteries are forced to overwork to compensate for the weaker ones, leading to premature failure for the entire investment. Starting with a matched set is the single best thing you can do for longevity.

Your Essential Toolkit

Once you have your matched set of batteries, it's time to assemble the gear for a professional-grade installation. Using undersized wires or making shoddy connections is a common mistake that leads to voltage drop, poor performance, and is a genuine fire risk.

Here’s what you'll need to have on hand:

- Hydraulic Crimper: A quality hydraulic crimper is non-negotiable for creating solid, permanent connections on thick battery cables. Don't be tempted by those cheap hammer-style crimpers; they're notoriously unreliable and not worth the risk.

- Heavy-Gauge Battery Cables: The correct wire size (gauge) is crucial. You’ll need short jumper cables to connect the batteries to each other and longer cables for the main RV connection.

- Correctly Sized Cable Lugs: These copper connectors must be a perfect match for your wire gauge and the battery terminal size. No exceptions.

- Heat Shrink Tubing: Always use adhesive-lined tubing (typically red for positive, black for negative) to seal your crimped connections. This protects them from moisture and corrosion, which can ruin a connection over time.

- Wire Cutters: You'll need a pair of heavy-duty cutters that can slice cleanly through thick battery cables without a struggle.

- Wrenches or Socket Set: For securely tightening the battery terminal connections.

- Safety Gear: At a minimum, always wear insulated gloves and safety glasses when working with batteries.

If you're working with lithium, it's also smart to brush up on essential LiPo battery safety measures. Proper handling and storage are just as important as the installation itself.

Choosing the Right Wire and Fuse Size

One of the most critical calculations you'll make is determining the correct wire gauge and fuse size for your system. This is absolutely not a place for guesswork. The size of the wire depends on two things: the total amperage your system will handle and the length of the cable run.

Thicker wire (which has a lower American Wire Gauge or AWG number) has less resistance. Less resistance means less voltage drop and less heat buildup. For instance, a system with a 2000-watt inverter can pull over 160 amps from your batteries. Using a wire that's too thin for that kind of load can cause it to overheat, melt its insulation, and become a serious fire hazard.

Similarly, a catastrophic main fuse or circuit breaker is your ultimate line of defense. It's designed to protect the wire, not the appliance. If a dead short ever occurs, the fuse blows, instantly cutting off the immense power stored in your battery bank and preventing a disaster.

Installing a master disconnect switch is another key safety and maintenance feature. Our guide on RV battery disconnect switch installation walks you through adding this important component step-by-step.

Here’s a table to give you a starting point for selecting the right components.

Wire Gauge and Fuse Sizing for Parallel RV Batteries

This table provides recommended wire gauge (AWG) and fuse amperage based on the total amp draw of your RV's inverter or main loads. Always consult your component manuals for specific requirements.

| Max Amp Draw (Inverter Size) | Recommended Wire Gauge (AWG) | Recommended Main Fuse/Breaker |

|---|---|---|

| 1000 Watts (~83 Amps) | 2 AWG | 100-125 Amps |

| 2000 Watts (~167 Amps) | 2/0 AWG | 200-250 Amps |

| 3000 Watts (~250 Amps) | 4/0 AWG | 300-350 Amps |

Remember, this is a general guide. It's always best to double-check the specifications from your inverter or battery manufacturer to be certain. When in doubt, go with a thicker wire—it's cheap insurance.

The Step-by-Step Parallel Wiring Process

Alright, you’ve got your matched batteries, properly sized cables, and tools laid out. Now it's time to put it all together. This is where a steady hand and a safety-first mindset are absolutely non-negotiable. I'll walk you through every action, from killing the power to making the final connections that will bring your new, high-capacity battery bank online.

Prepping Your Workspace: Safety First

Before a single wrench touches a terminal, you have to completely isolate your RV's electrical system. I can't stress this enough—this isn't a friendly suggestion, it's a critical safety command. A live wire accidentally touching your RV's metal frame can create a nasty shower of sparks, fry sensitive electronics, or much worse.

To get the system completely dead, follow these steps without fail:

- Disconnect Shore Power: Unplug your rig from any campground pedestal or home outlet. Simple as that.

- Turn Off Solar: If you're running a solar setup, find the circuit breaker or disconnect switch between your solar charge controller and the batteries. Flip it to the OFF position.

- Kill All Battery Power: Use your main battery disconnect switch (sometimes called a "salesman switch") to cut power to the house. If you don't have one, your first move will be to physically disconnect the main negative cable from your old battery setup.

Building Your Battery Cables Like a Pro

Professional-grade results come from professional-grade connections. Trust me, taking a few extra minutes here to build quality cables will pay you back for years in reliability and performance. I’ve seen more frustrating voltage drops and system failures caused by loosely crimped lugs or exposed wires than I can count.

Your main task here is to create short, identical "jumper" cables to link the batteries. Start by carefully measuring the distance between the positive terminal of your first battery and the positive terminal of your second. Always add a little slack for a gentle bend—wires pulled taut put a ton of stress on the terminals.

Once you have your measurement, use heavy-duty wire cutters for a clean, square cut. Then, with a utility knife or wire stripper, take off about ¾ inch of insulation from the end to expose the clean copper strands. Be careful not to nick or cut any of that copper, as this will reduce the wire's capacity.

Here's a pro tip: slide a piece of adhesive-lined heat shrink tubing over the wire before you crimp the lug on. Next, place the correct-sized copper lug over the exposed wire, making sure the strands are fully seated inside. Now, use your hydraulic crimper to create a rock-solid, permanent bond. A good crimp makes the lug and wire feel like a single, inseparable piece.

Finish it off by sliding the heat shrink tubing over the barrel of the lug and hitting it with a heat gun. The adhesive inside will melt, creating a tough, waterproof seal that protects your connection from corrosion and vibration—two of your battery bank's biggest enemies. Repeat this process for all your jumper cables.

Making the Parallel Connections

This is the heart of the project. The concept is simple: all the positive terminals get connected, and all the negative terminals get connected.

First, get your batteries situated in their final spot, leaving yourself enough room to work. Let's start with the positive connections. Take one of your red jumper cables and connect the positive (+) terminal of the first battery to the positive (+) terminal of the second. If you have a third battery, use another jumper to connect the positive of the second to the positive of the third, and so on. Snug the nuts on the terminals, but don't go crazy tightening them just yet.

Next, do the exact same thing for the negative side. Using your black jumper cables, connect the negative (-) terminal of the first battery to the negative (-) of the second. Just like before, continue this chain for all the batteries in your bank, linking all the negative terminals into one unified circuit.

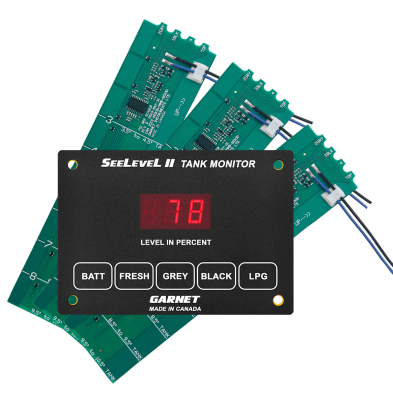

This is a great visual of the key parts you need for a safe and effective setup.

As you can see, success really hinges on three things working together: starting with perfectly matched batteries, using the right gauge wire for your connections, and protecting the whole system with a properly rated fuse.

The Secret to a Balanced, Long-Lasting Battery Bank

Now for what I consider the most important step in this entire process—and it's one that many DIYers get wrong. This single technique is the key to ensuring your batteries charge and discharge evenly, which is absolutely essential for getting the most life out of them.

Do not connect both of your main RV cables to the first battery in the bank. This is a common mistake called "daisy-chaining," and it creates an imbalanced system. The first battery does all the heavy lifting, leading to a premature death while the others are barely broken in.

Instead, we're going to connect your RV's main positive and negative loads to opposite ends of the bank. This simple trick forces the electrical current to travel through the entire bank equally, ensuring every battery pulls its weight.

Here’s exactly how to do it:

- Connect the Main Positive Cable: Attach your RV’s main positive load wire (the one that feeds your entire 12V system) to the positive (+) terminal of the first battery in your parallel chain.

- Connect the Main Negative Cable: Attach your RV’s main negative ground wire to the negative (-) terminal of the very last battery in the chain.

This cross-connection method is the gold standard for a balanced draw and charge. Once those final connections are made, go back and securely tighten down all the terminal nuts. They should be snug enough that you can't twist the lug by hand, but don't over-torque them and risk damaging the terminals.

And that's it! Your parallel battery bank is now wired for optimal performance and longevity.

Advanced Wiring for Large Battery Banks

When you move beyond a simple two-battery setup, how you wire everything together becomes exponentially more important. The basic cross-connection strategy I covered earlier works just fine for two batteries, but its magic starts to fade when you add a third, fourth, or even more into the mix. This is one of those areas where a lot of RVers accidentally sabotage their own investment without even realizing it.

The most common mistake is the "daisy-chain" method, where you just link batteries one after the other in a line. Electrically, this creates a path of least resistance. What that means in the real world is the first battery in the chain gets hammered with the most current during both charging and discharging. It does all the heavy lifting, while the poor battery at the far end of the chain barely breaks a sweat.

This imbalance is a silent killer for battery banks. The overworked first battery will degrade and fail way too early, often taking the rest of the bank down with it. You might have paid for a 400Ah system, but in reality, you're only getting the full, healthy performance out of a fraction of that capacity.

The Professional Solution: Bus Bars

To solve this problem for good, serious RV builders and marine electricians rely on a simple but incredibly effective component: bus bars.

Think of a bus bar as a central power hub. It's just a heavy-duty strip of conductive metal (usually copper) with a bunch of connection points. Instead of daisy-chaining, you run a separate, identically-lengthed cable from each battery's positive terminal to a positive bus bar. You do the exact same thing for the negative terminals, connecting each one to a negative bus bar.

From there, your main RV loads and all your charging sources (solar, converter, etc.) connect directly to the bus bars, not to an individual battery. This method forces electrical equality. Because every single cable is the same length, the resistance to and from each battery is identical. There’s no "easy path" anymore, so current is forced to flow evenly across the entire bank. Every battery contributes equally, ensuring they charge and discharge as one unified team.

Using bus bars is the single most important upgrade you can make when building a large battery bank. It moves your project from a simple DIY setup to a professional-grade power system designed for maximum longevity and performance.

A Real-World Example of Imbalance

This isn't just theory; you can see the difference in the real world. In one test of a three-battery system, the daisy-chain setup showed a massive 32-amp difference in charging current between the first and last battery.

But when the system was reconfigured with 250-amp heavy-duty bus bars, the charge distribution improved dramatically. The second battery started pulling in 41.4 amps and the third received 43.2 amps—almost perfectly balanced. You can dig into a detailed breakdown of these test findings on battery wiring configurations.

Key Advantages of Using Bus Bars

For anyone building a bank of three or more batteries, the benefits are undeniable. It might look like a bit more work upfront, but the long-term payoff is huge. If you’re planning a solar installation, this balanced approach is even more critical. You can see how this fits into the bigger picture by checking out our guide on creating an RV solar panel wiring diagram.

- Balanced Charging: Guarantees every battery gets an equal share of the charge current. This prevents chronically overcharging some batteries while undercharging others.

- Even Discharging: Ensures that all batteries contribute equally when you're powering your appliances, which maximizes your available capacity.

- Longer Battery Life: By eliminating the stress on a single battery, the entire bank ages gracefully and lasts significantly longer.

- Simplified Connections: Creates a clean, organized central point for all your high-amperage connections. This makes troubleshooting and future additions a whole lot easier.

Ultimately, when you're learning how to wire RV batteries in parallel for a large bank, embracing bus bars is the key. It’s how you protect your expensive battery investment and get the reliable, robust power system you need for serious off-grid adventures.

Wiring Lithium Batteries a Little Differently

Making the jump to lithium iron phosphate (LiFePO4) batteries is hands-down one of the best upgrades you can make to your rig’s power system. But these aren’t your grandpa’s lead-acid batteries; they play by a completely different set of rules.

Sure, they're lighter, last way longer, and you can drain them much deeper. That's the good news. The catch is that their unique chemistry demands a more thoughtful approach to your wiring.

Lithium batteries are absolute power hogs when it comes to charging. Most manufacturers recommend a charge rate of around 40 amps per battery, and believe me, you have to manage that current properly across your parallel bank to keep things happy. It's no surprise that lithium systems have exploded in popularity, jumping from under 5% of the RV market in 2015 to nearly 30% by 2024. RVers want performance, and lithium delivers.

Why Balanced Wiring Is Non-Negotiable

With old-school lead-acid batteries, a little bit of imbalance in your wiring wasn't a huge deal. It wasn't great, but it usually wouldn't cause a catastrophe. With lithium, it's a completely different story.

An imbalanced lithium bank can cause one battery’s internal Battery Management System (BMS) to shut down way too early, which can throw your whole system out of whack.

This is exactly why bus bars go from being a "nice-to-have" for big lead-acid banks to being pretty much mandatory for any lithium bank with more than two batteries. They are the single best way to make sure every battery is seeing the exact same voltage and current, keeping them all working in perfect harmony.

A lithium battery bank is only as strong as its weakest link. If one battery's BMS trips due to an imbalance, it can create a domino effect and take your entire power system offline right when you need it most.

The Critical Role of the BMS

Every quality LiFePO4 battery has an internal Battery Management System (BMS). Think of it as a tiny electronic brain that acts as the battery's bodyguard, constantly monitoring its vitals to prevent disaster.

Here’s what the BMS is always doing behind the scenes:

- Over-Charge Protection: It cuts off charging once the battery is full.

- Over-Discharge Protection: It shuts down the power before the battery drains too low, which would kill it for good.

- Temperature Monitoring: It won't allow charging or discharging if it's dangerously hot or cold.

- Cell Balancing: It works to keep all the individual cells inside the battery at the same state of charge.

When you wire multiple lithium batteries in parallel, each battery's individual BMS is still on the job. They don't talk to each other, but they all work to protect their own battery. If you've balanced your bank perfectly with bus bars and equal-length cables, all the BMS units should operate in sync without any issues.

Of course, a reliable system starts with choosing the right batteries in the first place. If you're just starting your research, our guide to the best RV battery for boondocking is a great place to compare some of the top lithium options on the market.

Beyond just the wiring, knowing how to properly handle and store these batteries is key. Taking care of them prevents serious safety issues and helps them last longer, so taking a few minutes to learn about safely storing lithium batteries is time well spent. At the end of the day, wiring lithium batteries in parallel isn't any harder, it just demands more precision to protect your investment.

Common Questions About Parallel RV Battery Wiring

Even when the install goes smoothly, a few questions always seem to pop up. When you're dealing with your RV's power system, there's no such thing as being too careful. Let's tackle the most common uncertainties people have so you can wrap up your project with total confidence.

Can I Mix Old and New Batteries in a Parallel Bank?

I get this question all the time, and the answer is a hard no. It's one of the fastest ways to destroy a brand-new battery and cripple your entire bank. When you mix batteries of different ages, the new, healthy battery gets dragged down to the performance level of the oldest, weakest one.

Think of it this way: the older battery has higher internal resistance, so it struggles to take a charge and deliver power. This puts all the stress on the new battery, forcing it to do the heavy lifting during both charging and discharging. The result? It wears out in a fraction of the time.

Always use batteries that are identical in every way—same manufacturer, model, chemistry (AGM, LiFePO4, etc.), capacity, and, most importantly, age. Treat your battery bank as a single, unified component.

Do I Need a Special Charger for Parallel Batteries?

It really depends on what kind of batteries you're using. If you have traditional lead-acid batteries (like flooded or AGM), your existing multi-stage RV converter charger will probably work just fine. Your charger simply sees the parallel bank as one big battery and adjusts its charging profile to match.

The real consideration is whether your charger has enough juice for the new, larger capacity. A small 30-amp charger will take forever to replenish a 400Ah bank, so an upgrade might be in order.

However, if you've switched to LiFePO4 (lithium) batteries, a charger with a specific lithium charging profile is mandatory. Using a standard lead-acid charger will never fully or properly charge them, which will seriously shorten their lifespan and hurt their performance.

What Is the Difference Between Parallel and Series Wiring?

This is a fundamental concept that trips a lot of people up, but getting it right is critical for your RV’s entire electrical system. Mixing these up can easily fry your appliances.

- Parallel Wiring: This is when you connect positive-to-positive and negative-to-negative. It increases your amp-hours (runtime) but keeps the voltage the same. Two 12V 100Ah batteries wired in parallel become a single 12V 200Ah bank.

- Series Wiring: This is when you connect positive-to-negative, creating a chain. It increases your voltage while the amp-hours stay the same. Two 12V 100Ah batteries wired in series become a 24V 100Ah system.

For pretty much any standard RV that runs on a 12-volt system, parallel wiring is what you want for your house batteries. Series wiring is for specific applications that need higher voltage, like some golf carts or massive off-grid power systems.

How Many Batteries Can I Safely Wire in Parallel?

This all comes down to how you wire them.

If you use the cross-connection method we talked about (main positive to the first battery, main negative to the last), you can usually get away with up to four batteries without major balancing issues. That method does a decent job of distributing the load across a smaller bank.

But for banks with more than four batteries, you really need to use bus bars. As you daisy-chain more and more batteries together, the ones stuck in the middle get neglected. They don't charge or discharge evenly with the batteries on the ends. Bus bars fix this by creating equal-length cable paths to every single battery, ensuring the whole bank works together as a perfectly balanced team. Without them, you're just building an inefficient system that won't last.

At RVupgrades.com, we stock all the high-quality components you need for a safe and reliable battery upgrade, from correctly sized cables and lugs to heavy-duty bus bars and fuses. Explore our vast selection of RV electrical parts and get your project done right.