Before you even look at an rv solar panel wiring diagram, let’s talk about the single most important step: figuring out what you actually need to power. I’ve seen it a hundred times—RVers jump straight to buying panels and wires, get excited about the project, and then end up with a system that can’t even run their coffee maker. Or, just as bad, they spend a fortune on an oversized setup they’ll never fully use.

A little planning upfront will save you a massive amount of frustration and money. Trust me on this.

Planning Your System Before You Touch a Wire

The foundation of a solid RV solar system isn't the shiny panels on the roof; it’s the simple math you do before you buy anything. This process is called a power audit, and it’s your roadmap for the entire project. It tells you exactly how much juice you use every day, which dictates the size of your solar array, battery bank, and inverter.

Without this audit, you're just guessing. Think of it like packing for a trip. You wouldn't just throw random clothes into a suitcase; you’d consider the weather and what you’ll be doing. A power audit is the same idea but for your electricity needs. It ensures you have exactly what you need for your off-grid adventures, nothing more and nothing less.

Conducting Your RV Power Audit

"Power audit" might sound technical, but it's just making a list of your daily electrical usage. The goal is to calculate your total daily watt-hours (Wh), which is the universal language of energy consumption.

Here’s a practical way to get it done:

- List Every Device: Grab a notepad and walk through your RV. Write down every 12V DC and 120V AC appliance you plan on using off-grid. Be brutally honest—lights, water pump, vent fans, laptops, phone chargers, TV, microwave, and that all-important coffee maker.

- Find the Wattage: Look for a sticker on each device (or its power brick) to find its consumption in watts (W).

- Estimate Daily Use: Next to each item, jot down how many hours you realistically see it running each day. Your fridge might cycle on and off 24/7 (a good estimate is 8 hours of total run time), but the microwave might only run for 10 minutes total.

- Do the Math (Watt-Hours): Multiply the watts by the hours for each device. For instance, a 10W LED light used for 5 hours a day is 50 Wh. A 900W microwave running for 10 minutes (0.17 hours) is 153 Wh.

Add up the watt-hours for everything on your list. That final number is your daily energy target. It’s the figure that will guide every single purchase from here on out.

Understanding the Core Components

Once you know your daily watt-hour needs, you can start picking the right tools for the job. Every part of a solar system has a specific role, and they all have to work together.

- Solar Panels: These are your power plants. Their job is to turn sunlight into DC electricity. The total wattage of your solar array needs to be large enough to replace the energy you use each day, plus about 25% extra to account for cloudy days and system inefficiencies.

- Charge Controller: This is the brain of the operation. It sits between your panels and your batteries, regulating the voltage and current to prevent overcharging. I always recommend an MPPT (Maximum Power Point Tracking) controller for RVs—they are significantly more efficient than older PWM models and squeeze every last drop of power from your panels, especially on cloudy days.

- Battery Bank: This is your energy savings account. It stores power so you can use it at night. The capacity, measured in amp-hours (Ah), must be large enough to cover your daily watt-hour total without being drained too low. For lithium (LiFePO4) batteries, you can safely use about 80% of their capacity. For lead-acid, you should only use 50% to avoid damaging them.

- Inverter: This converts the 12V DC power from your batteries into 120V AC power for household appliances like microwaves and laptops. The inverter's size (in watts) must be large enough to handle the combined power draw of any AC devices you might run at the same time.

A classic rookie mistake is undersizing the inverter. If your coffee maker needs 1200 watts to fire up, a 1000-watt inverter is going to trip every single time. Always size your inverter to handle your biggest power hogs, and add about 20% extra headroom just to be safe.

Series vs. Parallel Wiring for RV Solar Panels

Once you’ve got a solid plan, the real technical decisions begin. This is where your RV solar panel wiring diagram starts to take shape, and one of the first forks in the road is deciding whether to wire your solar panels in series or in parallel. This isn’t a minor technical detail; it’s a critical choice that directly impacts how well your system performs, especially on a cluttered RV roof.

Choosing the right configuration can be the difference between a system that pumps out reliable power and one that sputters every time a shadow from a vent pipe falls across a single panel. Let's break down these two approaches with a real-world example.

Understanding Series Connections

Wiring solar panels in series is like stacking batteries in a flashlight. You connect the positive (+) terminal of one panel to the negative (-) terminal of the next, creating a simple chain.

When you wire panels in series, their individual voltages add up, while the amperage (current) stays the same as a single panel.

Example Scenario: Four 100W Panels

Let's imagine you have four 100-watt panels, and each one is rated for about 18 volts (V) and 5.5 amps (A).

- In Series: The total voltage skyrockets to 18V + 18V + 18V + 18V = 72 volts.

- The Amperage: The amperage remains at 5.5 amps.

This high-voltage output is incredibly efficient, especially with a modern MPPT charge controller. Higher voltage travels more easily over the long wire runs from your roof down to your controller with less power loss, which means you can often use thinner, less expensive wire.

But here’s the big catch with series wiring: it’s extremely vulnerable to shade. If even one panel in the chain gets partially covered by a tree branch or an air conditioning unit, the output of the entire string can plummet. It’s like a kink in a hose—the weakest link dictates the flow for the whole system.

Exploring Parallel Connections

Parallel wiring takes the opposite approach. You connect all the positive terminals together and all the negative terminals together, usually with branch connectors or a combiner box on the roof.

In a parallel setup, the voltage stays the same as a single panel, but the amperage from each panel adds up.

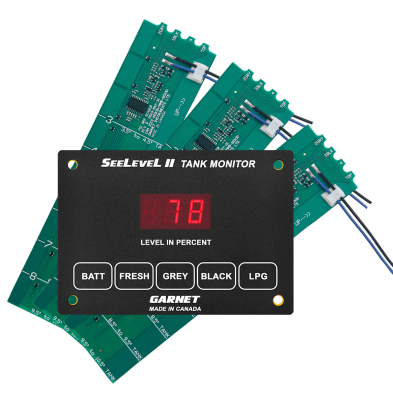

This infographic simplifies the initial decision-making process, from identifying your power needs to selecting the right components for your chosen wiring strategy.

This visual shows how your wiring choice between series and parallel logically follows after you've figured out your system's size and the components you'll be using.

Example Scenario: Four 100W Panels

Using those same four 100-watt panels (18V, 5.5A each):

- The Voltage: The voltage stays steady at 18 volts.

- In Parallel: The amperage becomes 5.5A + 5.5A + 5.5A + 5.5A = 22 amps.

The killer advantage here is shade tolerance. If one panel gets shaded, the other three keep pumping out power like nothing happened. This makes parallel setups incredibly resilient for RVs that park in unpredictable conditions. For more on different setups, you can find a wealth of insights about RV solar panel configurations on shopsolarkits.com.

Which Wiring Diagram Is Right for Your RV?

So, how do you choose? It boils down to a few factors specific to your rig and how you use it. There’s no single “best” answer, only the best answer for you.

Ask yourself these questions:

- How much shade will your panels see? If you frequently park under trees or have a roof crowded with antennas, vents, and an AC unit, parallel is almost always the safer bet.

- How long is the wire run to your charge controller? For long runs (over 20-25 feet), the higher voltage of a series connection can be more efficient and fight voltage drop.

- What type of charge controller do you have? MPPT controllers love the high voltage from series-wired arrays, as they can efficiently convert it into usable current. Older PWM controllers work best with parallel setups where the panel voltage is much closer to the battery voltage.

For the vast majority of RVers, the superior shade tolerance of a parallel system is the deciding factor. The unpredictable nature of campsites means you can rarely guarantee a perfectly sun-soaked roof, making parallel the more reliable and practical choice for consistent power generation on the road.

Wiring Your Charge Controller and Battery Bank

Alright, your panels are on the roof. The next major step in your rv solar panel wiring diagram is to bring that power inside to the system’s heart: the charge controller and the battery bank.

The charge controller is the brain of the operation. It manages the flow of energy to make sure your expensive batteries don't get overcooked. Your battery bank is the reservoir, storing all that solar power.

Getting these components wired correctly isn't just about making it work—it’s about safety and protecting your investment. One wrong move here can damage your gear or create a dangerous electrical situation. Let’s walk through it, focusing on the right sequence and safety steps you can't skip.

The Golden Rule of Controller Wiring

If you only take one thing away from this section, make it this: always connect the battery to the charge controller before connecting the solar panels. This is the most critical step in the entire process.

Here's why: a charge controller needs to sense the battery's voltage first (whether it's a 12V or 24V system) to set up its charging parameters correctly. If you hook up the solar panels first, the controller gets hit with unregulated, high-voltage power with nowhere to send it. This can instantly confuse or fry the electronics inside.

The connection order is always the same:

- Controller to Battery: Run your positive and negative wires from the battery bank to the corresponding battery terminals on the charge controller.

- Panels to Controller: Only after the controller has powered on from the battery, connect the positive and negative leads from your solar array to the solar inputs on the controller.

When it's time for maintenance, reverse the order. Disconnect the solar panels first, then disconnect the battery.

This sequence is non-negotiable. I've seen DIYers fry brand-new MPPT controllers simply by hooking up the panels first. It's an easy and costly mistake.

Sizing Your Controller and Fuses

A common setup of four 100W panels, for a total of 400 watts, can pump out around 33 amps in full sun. Your charge controller must be rated to handle that current, which is why 30A or 40A controllers are popular choices. You can see how these components fit into a complete system by checking out the detailed solar charging wiring diagrams and setups on explorist.life.

Just as important is installing fuses or circuit breakers. These are your system's safety valves. They protect against short circuits and overloads that could lead to a fire.

You need one in two key spots:

- A fuse or breaker between your solar array and the charge controller.

- A fuse or breaker between the charge controller and the positive terminal of your battery bank.

Wiring Your 12V Battery Bank in Parallel

For nearly every RV application, the goal is to build a high-capacity 12V battery bank. Capacity is measured in Amp-Hours (Ah). To get that big capacity while keeping the voltage at 12V, you’ll wire multiple 12V batteries together in parallel.

Parallel wiring is straightforward: connect all the positive terminals together, and then connect all the negative terminals together. This keeps the system voltage at 12V but adds the Amp-Hour capacity of each battery. For instance, hooking up four 100Ah batteries in parallel gives you one large 12V bank with a 400Ah capacity.

Here’s a pro tip for connecting your loads (like the charge controller and inverter) to the bank: connect the main positive cable to the positive terminal of the first battery in the line, and the main negative cable to the negative terminal of the last battery. This helps the batteries charge and discharge more evenly, extending their overall lifespan.

How to Connect an Inverter to Your RV System

So far, all the power you've generated and stored is 12V DC. That’s great for your RV’s native lights, water pump, and fans, but it’s useless for your coffee maker, microwave, or laptop.

This is where the inverter comes in. It transforms that 12V DC battery power into the 120V AC household power your everyday appliances need. Getting this part right is a game-changer for off-grid comfort.

But this is also where the stakes get higher. Inverters pull a massive amount of current from your batteries. A sloppy installation isn’t just inefficient—it’s a serious fire hazard. Let's walk through the rv solar panel wiring diagram for a simple standalone setup versus a more integrated system.

Wiring a Standalone Inverter

The most basic approach is wiring an inverter directly to your battery bank. This is perfect if you just want to run an extension cord to a specific appliance or power one or two dedicated outlets. The concept is simple, but the execution must be precise.

Because inverters are so power-hungry, the cables connecting them to your batteries need to be seriously thick. We’re often talking 2/0 or even 4/0 gauge wire, depending on the inverter's wattage and distance from the batteries. Using undersized wires is a recipe for disaster—they’ll get dangerously hot, cause a major voltage drop, and choke your inverter, preventing it from working correctly.

The wiring path is straightforward:

- A heavy-gauge positive cable runs from the battery's positive terminal to the inverter's positive terminal.

- A heavy-gauge negative cable runs from the battery's negative terminal to the inverter's negative terminal.

The single most important safety device here is a large fuse or circuit breaker on the positive cable, installed as close to the battery as you can possibly get it. This is non-negotiable. If a short ever happens inside the inverter, that fuse is the only thing standing between you and a potential fire.

Integrating an Inverter with Your RV's AC System

For a seamless "just like home" experience, you can integrate an inverter/charger directly into your RV’s main AC breaker panel. This setup powers all your existing outlets without you fussing with extension cords. Plus, these units usually have a powerful multi-stage battery charger built-in, which works anytime you're plugged into shore power.

This is a more advanced installation that almost always involves an automatic transfer switch. This smart device knows where your AC power is coming from.

When you’re plugged in at a campground, it routes shore power to your breaker panel. The second you unplug, it instantly flips over, letting your inverter take over and power those same circuits. It makes the transition effortless.

The wiring diagram gets more involved here. The inverter's AC output feeds into the transfer switch, and the transfer switch's output feeds your main AC panel. Your shore power cord also connects to an input on the transfer switch. This ensures your system can't accidentally try to back-feed the grid or have two power sources fighting each other.

Proper grounding is absolutely critical. The inverter's chassis needs a solid ground connection to the RV's frame to prevent any risk of electrical shock. High-quality inverter kits, like those from suppliers such as RVupgrades.com, typically include detailed instructions for a safe, reliable installation. Following those diagrams carefully is key to making sure all your AC appliances work safely, whether you're off-grid or plugged in.

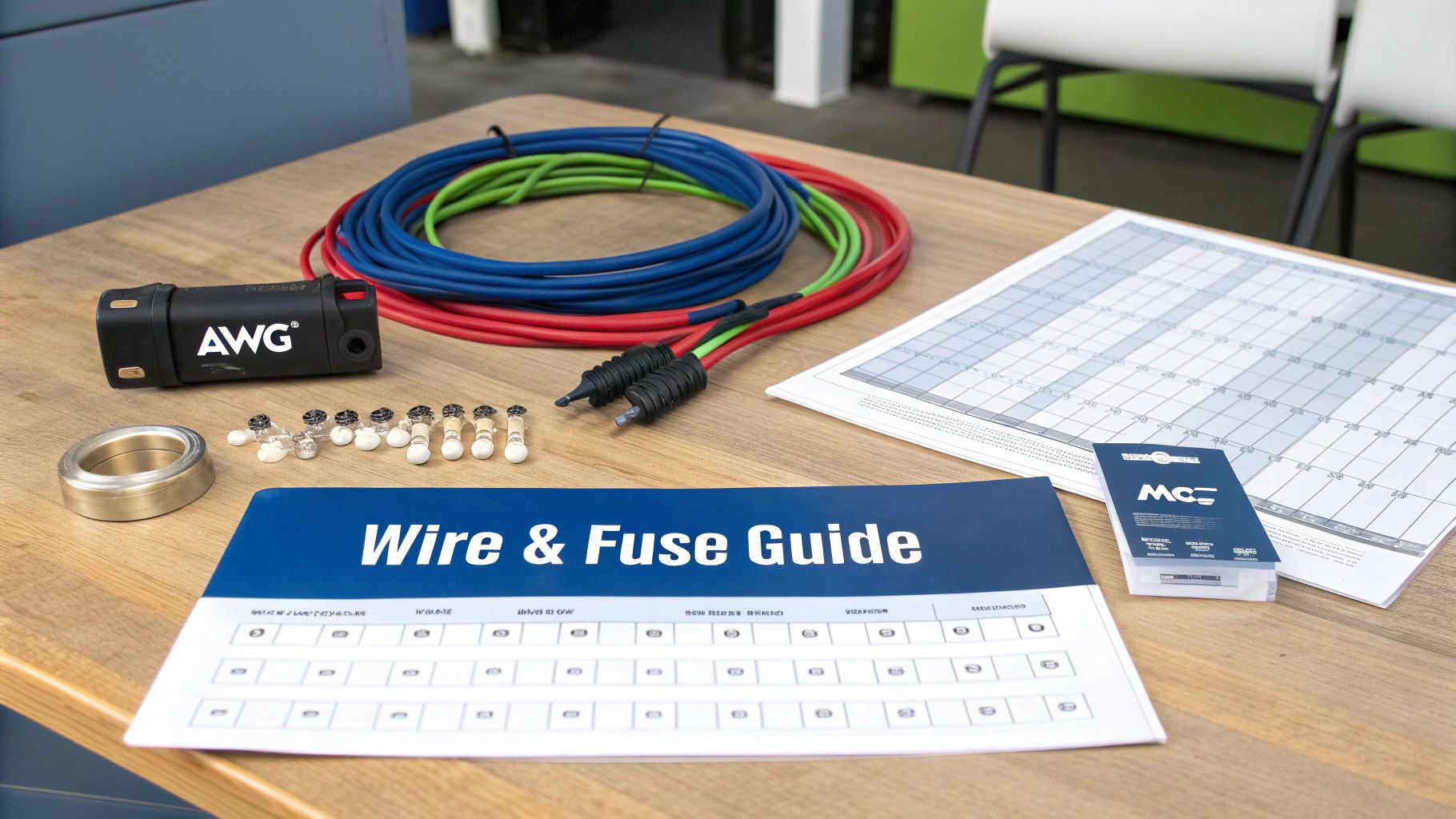

Selecting the Right Wires, Fuses, and Connectors

Once the big components are planned, it’s time to zero in on the parts that connect everything. This is where a good system becomes a great one. Choosing the right wires, fuses, and connectors is critical for preventing power loss and, more importantly, avoiding a fire hazard.

Using undersized wire is one of the most common mistakes. Think of it like trying to drink a thick milkshake through a tiny coffee stirrer—it just doesn't work well. The wire heats up, you lose precious power to resistance (called voltage drop), and your expensive components won't perform as they should.

Choosing the Correct Wire Gauge

Wire thickness is measured in American Wire Gauge (AWG). It’s counterintuitive, but a smaller AWG number means a thicker wire. The right gauge depends on the current (amps) flowing through the wire and the total length of the wire run.

And here’s a key detail: you must calculate the round-trip distance—from the component, to the battery, and back again.

Your main goal is to keep voltage drop below 3%. Any more than that, and you're throwing away the power your panels worked so hard to generate. This is especially true for the high-current connection between your battery bank and your inverter.

Recommended Wire Gauge (AWG) for 12V Systems

To make this simple, here’s a quick-reference chart for 12V systems designed to keep voltage drop under 3%. Just find your component’s maximum amperage on the left and the total wire length across the top to find the minimum AWG wire you should use.

| Current (Amps) | 5-10 feet | 10-20 feet | 20-30 feet | 30-40 feet |

|---|---|---|---|---|

| 0-20 A | 10 AWG | 8 AWG | 6 AWG | 4 AWG |

| 20-30 A | 8 AWG | 6 AWG | 4 AWG | 2 AWG |

| 30-50 A | 6 AWG | 4 AWG | 2 AWG | 1/0 AWG |

| 50-100 A | 4 AWG | 2 AWG | 1/0 AWG | 2/0 AWG |

This table provides a solid starting point for most RV applications. When in doubt, always go one size thicker. You can never have a wire that's too big, but you can definitely have one that's too small.

Sizing and Placing Fuses Correctly

Fuses and circuit breakers are your system's non-negotiable safety net. A common misconception is that they protect your equipment; in reality, they're there to protect the wires from catching fire. A fuse must be sized to blow before the wire it’s protecting reaches a dangerous temperature.

A good rule of thumb is to size the fuse or breaker about 25% higher than the maximum continuous current expected on that wire. For instance, if your solar array can produce a maximum of 30 amps, a 40-amp fuse between the panels and the charge controller is a perfect choice.

Every single positive wire connected to your battery bank's positive terminal needs its own fuse, placed as close to the battery as physically possible.

- Solar Panels to Charge Controller: Protects the system from a short in the controller.

- Charge Controller to Battery Bank: Protects the wire from a potential battery fault.

- Inverter to Battery Bank: This is the big one, often requiring a massive 200A or 300A fuse.

- DC Fuse Box to Battery Bank: Protects all your smaller 12V circuits running lights, fans, and pumps.

I once helped a fellow RVer who couldn't figure out why his new inverter kept faulting. He'd used the correct thick-gauge wire but skipped the fuse. A quick inspection revealed a tiny internal short in the brand-new inverter. Without a fuse, the massive current from his lithium batteries was causing the voltage to crash instantly. A properly sized fuse would have blown immediately, making the problem much easier to diagnose.

Using the Right Connectors for Solid Connections

Finally, the hardware holding it all together matters immensely. I've seen more systems fail from bad connections than anything else. Poor connections create resistance, which generates heat and causes power loss.

- MC4 Connectors: These are the industry standard for solar panels for a reason. They are waterproof, UV-resistant, and create a secure, locking connection that won't jiggle loose while you're bouncing down the highway.

- Ring Terminals: For connecting large cables to batteries, inverters, and bus bars, use high-quality, closed-end copper ring terminals. Use a proper hydraulic or lever-action crimping tool—not a hammer or pliers. A solid crimp creates a permanent mechanical and electrical bond. A little heat-shrink tubing over the connection provides a clean, professional finish and adds strain relief.

Taking the time to select the right components ensures your system is not only powerful but also safe and reliable for years of off-grid adventures.

Diagnosing Common Solar Wiring Issues

Even with the best planning and a perfect rv solar panel wiring diagram, things can go wrong. Your system might seem sluggish, or not work at all. When frustration kicks in, don't panic. Most solar wiring problems are common and, with a methodical approach, easy to track down.

Grab a multimeter—it's your best friend for this job. Work logically through the system from the panels to the batteries. The multimeter will give you the hard data you need to check for continuity, confirm voltage, and test polarity at every critical connection, letting you pinpoint the problem.

With a little patience, you can almost always find the source of the issue and get things running smoothly again.

Common Problem: Batteries Aren’t Charging

This is probably the most frequent issue RVers run into. You’ve got bright sunshine, but the battery monitor shows zero amps flowing into your bank. The culprit is usually something simple.

Start your investigation by checking the most obvious failure points first.

- Check Your Fuses and Breakers: Always start here. Check the fuse or breaker between your solar array and the charge controller, then the one between the controller and your batteries. A blown fuse or tripped breaker is the number one cause of a dead system.

- Confirm Polarity: Reversed polarity is another easy mistake to make. Use your multimeter to confirm the positive wire from the panels is landed on the positive terminal on the controller, and the same for the negative. Do this again for the wires between the controller and the battery bank.

- Test Panel Voltage: Unplug the solar panel wires from your charge controller. On a sunny day, test the voltage across the positive and negative leads coming from the panels. You should see a reading—called Open-Circuit Voltage or Voc—that’s typically between 18V to 22V for a standard 12V panel. If you get zero volts, the problem is on your roof, likely a loose MC4 connection or a damaged wire.

The Sneaky Impact of Partial Shading

One of the most deceptive issues, especially for arrays wired in series, is partial shading. Panels wired in series are extremely sensitive to this; shading just one panel can tank the power output of the entire string, sometimes to almost nothing.

This is why parallel wiring is often a better choice for RVs. Each panel operates independently, so a shaded panel only reduces its own output, not the whole array's. For example, a set of panels might produce 500 watts in full sun. With partial shading, a series-wired system might drop to nearly 0 watts, while a parallel system might only dip to 400 watts. You can see more real-world data on electrical system performance over at faroutride.com.

I once spent an hour troubleshooting a friend's new series-wired system that was producing almost no power on a sunny day. The culprit? The tiny shadow from a vent pipe was falling across the corner of a single panel, effectively shutting down his entire 400-watt array. We switched his setup to parallel, and the problem vanished.

Troubleshooting an Inverter That Keeps Shutting Down

Another common headache is an inverter that constantly shuts down or beeps with a low voltage alarm, even when the batteries are full. This almost always points to an issue on the high-current DC side of your system.

The main suspect here is voltage drop. When your inverter fires up a big load like a microwave, it pulls a massive amount of current. If the cables connecting it are too small or a connection isn't perfectly tight, the resistance creates a huge voltage drop. The inverter sees this sudden dip in voltage and shuts down to protect itself, even though the batteries themselves are healthy.

To fix this, go back and double-check your wire gauge against a proper sizing chart. Make sure your cable runs are as short as possible, and that every single ring terminal is securely crimped and tightened. A single loose connection at the battery terminal or inverter can create enough resistance to bring your whole AC system to its knees.

For all the premium components you need to build a reliable and safe RV solar system—from correctly sized wires and fuses to top-tier charge controllers and inverters—check out the extensive selection at RVupgrades.com. Find everything you need for your DIY project at https://www.rvupgradestore.com.